Types and Applications of Flexible Bollards: The Best Choice for Improving Industrial Safety

With the increase in factory safety awareness, more and more companies and factories are starting to build with flexible bollards. This kind of flexible guardrail can prevent vehicles, machinery or other means of transportation from hitting a specific area or equipment, reducing the risk of accidents pick. Not only can it effectively absorb the impact brought about by the collision and alleviate the degree of personnel injuries. But also it has the advantages of fire prevention, corrosion resistance, durability and so on. It is an indispensable and important part of industrial safety. In this article, we will introduce the types and characteristics of the flexible bollards avoidance column, in order to choose the right product for you.

What is a Flexible Bollard?

Definition

Flexible bollard is a device used to protect equipment, facilities and personnel from vehicle collision, and a physical means of combining with traffic management. The purpose is to prevent, control, and reduce accidents and forklift collisions. Flexible anti-collision pillars are effective in mitigating the impact of collisions and reducing the occurrence of damage and injury.

Background

According to the International Labor Organization (ILO), the number of deaths and injuries caused by industrial accidents worldwide is huge every year, especially in high-risk production, warehousing and logistics industrial environments. Flexible bollards are used as an economical and effective means of protection. Widely used in various types of industrial places to reduce the occurrence of accidents.

Types and Applications of Flexible Bollards: The Best Choice for Improving Industrial Safety

Categorized by material:

Rubber Bollards

Rubber Bollards are made of high quality rubber. This material is characterized by high elasticity and is able to absorb the impact of a collision and return to its original state. Therefore, it is ideal for various industrial places to reduce the damage caused by the collision of transportation vehicles.

Application: Durable and elastic, suitable for high-frequency impact locations.

Plastic Bollard Covers

Plastic bollard covers are generally lighter than rubber or metal bollards. Because plastic is less resilient, it can withstand light impacts. However, plastic bollards are resistant to most industrial chemicals and are suitable for use in chemical storage areas or in environments with high levels of moisture.

Application: Lightweight and low cost, but suitable for low impact, low risk areas.

Polymer Flexible Bollards

Polymer Flexible Bollards are an elastic and high tenacity safety facility with internal reinforcing structural tendons that can defuse most of the energy. It is mainly used to prevent vehicles, machinery or other means of transportation from hitting specific areas or equipment. Unlike traditional metal or concrete crash barriers. Polymer Flexible Bollards are made of high polymer material with good flexibility and toughness. It is able to quickly recover its original shape after being impacted, preventing vehicle damage and personnel injury.

Application: With strong elasticity and corrosion resistance, it is suitable for long time use.

Steel Safety Bollards

Steel crash protection bollards are the ideal solution for protecting your property from accidental vehicle damage. Made from steel with reflective stripes that are both eye-catching and highly durable. It provides reliable protection against costly damage. It is simple to install and requires low maintenance, making it a practical choice for any property. Whether it’s for commercial, industrial or residential use, this steel safety bollards will ensure the safety of your plant.

Application: Sturdy and commonly used where a high level of security is required, such as factories and airports.

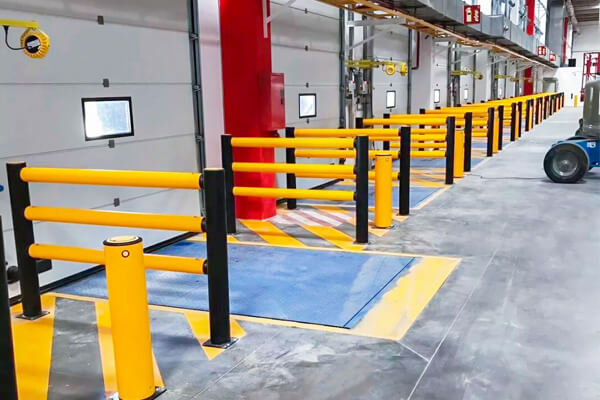

Flexible Anti-collision Guardrail

Flexible anti-collision guardrail is a type of guarding measure that has significant advantages over traditional guardrails and can better protect personnel and forklifts on the factory floor. The flexible structure of flexible guardrail can absorb and disperse the impact force, reducing the degree of injury to personnel. It plays a key role in factory workshops. At the same time, polymer flexible crash guardrail is easy to install and maintain. And it is used for a long time, which reduces the frequency of maintenance. Therefore, it is recommended to use polymer flexible crash barriers in factory workshops to provide a safer working environment for employees and equipment, and to promote the improvement of productivity.

Application: With strong elasticity and corrosion resistance, it is suitable for long time use.

Tough Soft Curtain Anti-Collision Guardrail

Tough soft curtain anti-collision guardrail is made of red PVC material and high-strength nylon belt. It can withstand a maximum of 5000KG, and the combination of red and yellow color makes the guardrail more eye-catching and provides a warning function.

Application: The soft curtain safety barriers are mainly used to provide effective safety protection for loading dock levelers and other areas. Prevent forklifts, or people from accidentally falling from the loading dock area.

Categorized by design form:

Visible Warning Column

Can usually have bright colors (yellow, red, orange, etc.) and reflective strip design to increase visibility in low light or nighttime environments. Through reflective strips, warning signs and other designs, pedestrians and drivers are alerted to obstacles and accidents are reduced. Anti-collision warning columns of this design are commonly used in areas with high traffic flow to effectively guide traffic and avoid accidental collisions. Visual Collision Avoidance Pillar.

Application: Suitable for areas with frequent vehicle access, such as warehouses, factory gates, loading dock areas. Especially at night or in the case of insufficient light, it has a significant warning effect.

Spring-loaded Collision Avoidance Post

This type of collision avoidance post has a built-in spring system, which can quickly recover after a collision, and is suitable for frequent collision environments. Spring-loaded bollards maintain good performance after many impacts and have a long service life. Especially suitable for equipment and personnel-intensive areas. They can mitigate the impact of a vehicle crash and protect the surrounding facilities.

Application: Suitable for industrial areas where vehicles frequently enter and exit. Such as warehouses, logistics centers, cargo loading and unloading areas, etc.

Parking Foldable Column

Foldable design facilitates the use of collision avoidance bollards to be adjusted according to the needs, suitable for places that need to adjust the passing area during non-working hours or low traffic. The collapsible design can be retracted when not required, saving space and allowing for temporary adjustments to the road layout. Usually equipped with a locking device, they can be quickly installed and removed when in use, making them easy to manage and operate.

Application: Suitable for use in places that need to temporarily adjust the passing area. Such as parking lots, residential areas and other places that do not affect the aesthetics.

Key Features and Benefits of Flexible Bollard Posts

Improving industrial safety

Most of the flexible bollard posts are set up in front of the high-speed door track at the position of 50MM. To prevent the transportation tools, forklifts, etc. from colliding with the production equipment or workers, and to reduce the rate of accidents. At the same time, there are reflective stickers or other signs of slowing down, providing obvious visual signs. So that passing vehicles or forklift drivers can see it from a long distance, avoiding accidental collisions caused by visual blind spots.

High Flexibility and Durability

Flexible collision avoidance post adopts unique flexible energy-absorbing material technology. Which makes it possible to quickly absorb the impact energy and disperse it throughout the structure upon impact, thus minimizing the impact of the impact on the equipment. At the same time, this material has a high degree of toughness, and can rebound to the initial state after multiple impacts. Flexible bollards are able to withstand multiple collisions, maintain guaranteed long-term stability, and reduce the frequency of replacement.

Reduced Maintenance Costs

Flexible collision guardrail is also characterized by easy installation and maintenance. Because of its material has good weather resistance and corrosion resistance. It is not easy to be affected by the external environment. And only need to carry out simple cleaning and inspection on a regular basis to maintain its normal use. Compared with steel bollards, flexible bollards can regain their shape after damage, so they are used more frequently. In high-impact environments, bollards can reduce facility damage, thereby reducing the cost of safety incidents.

Improved accessibility

The bright colors of flexible bollards alert drivers to warnings and avoid dangerous areas. When installed in industrial locations, bollards prevent vehicles from entering hazardous areas, ensure smooth production processes and improve logistics efficiency.