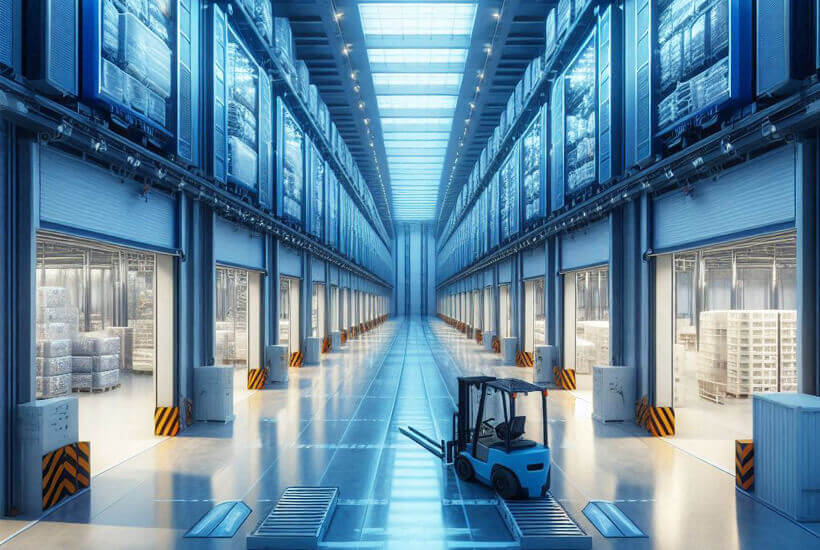

Cold Storage Door Solutions: Managing Your Energy Costs For Cold Room

With the rapid development of the global economy. The demand for cold storage in the logistics, food and pharmaceutical industries is increasing day by day. As one of the core equipment for cold chain warehousing, cold storage door is an important facility to ensure product freshness and quality. And fast door has a significant impact on both temperature control and energy saving. Advances in technology have led to the continuous development of cold storage door types. Their functions have become more diversified. This article will introduce the types of cold storage doors and discuss in detail why choosing the right cold storage door is critical to temperature stability and energy efficiency optimization.

Common Types of Cold Storage Door

Cold room sliding door

Insulated high speed door

Hinged cold room doors

Why are Cold Storage Doors the Best Choice for Temperature Control?

Efficient temperature isolation performance

Cold storage door adopts high-density insulating material, which perfectly combines the sealing structure and multi-layer thickened curtain. It ensures that the insulated high speed roll up door minimizes cold air leakage when opening and closing, and effectively maintains a stable temperature inside the storage. Avoid the influence of outside temperature and humidity and maintain a stable cold storage environment. More importantly, this temperature isolation performance is important for preventing energy waste and reducing the company’s operating costs.

Fast opening and closing design

The rapid operation function brings many benefits to the freezer door. Rapid opening and closing of the door reduces air loss and maintains a constant temperature in the warehouse during frequent use. Especially in situations where goods need to be moved in and out frequently. The efficient design of the cold room sliding door dramatically improves work efficiency.

Anti-condensation and heat preservation technology

As cold storage doors are often used in extremely low temperature environments. Modern cold storage doors are often equipped with anti-condensation systems. This system for insulated doors effectively prevents water vapor from condensing on the surface of the door, ensuring the stability and safety of the door for long-term use. In addition, insulation technology can significantly improve the energy efficiency of cold rooms.

The Importance of Cold Room Doors for Your Facility

In any cold room, the cold storage door is a key factor in temperature control and energy efficiency performance. The following aspects explain why the right cold room doors are the best choice for ensuring temperature stability and optimizing energy efficiency:

Temperature retention

The sealing of freezer door plays a decisive role in the temperature exchange between the inside and outside. High-quality cold storage doors are often equipped with multiple seals that minimize air leakage. It can ensure that the temperature inside the cold storage is maintained within the desired range. Especially for ultra-low temperature cold rooms. The sealing performance of the door is directly related to the stability of the internal temperature.

Energy efficiency

Energy efficiency is crucial to cold storage operation, and the freezer door is one of the main factors affecting energy consumption. Frequent opening of the high speed freezer door without good insulation performance will lead to a large amount of cold air loss. Which increase the load of refrigeration equipment, and thus enhance energy consumption. Cold storage doors with excellent thermal insulation performance can effectively reduce energy loss and help enterprises save power expenses.

Convenient and safe operation

In addition to temperature control and energy efficiency performance, modern cold storage doors also emphasize operational convenience and safety. For example, cold storage doors with automated opening and closing functions can reduce the opening time to further minimize the loss of cold air. Also some doors are equipped with anti-pinch design to enhance the safety of operation.

Durability and maintenance cost

Cold storage roller doors are used more frequently, so their durability and maintenance costs are also key considerations. The choice of corrosion-resistant and wear-resistant materials not only extends the service life of the door. But also high speed freezer door reduces the frequency of regular maintenance and lowers the long-term cost of use.

How to Choose the Right Cold Storage Door for Your Needs

Selecting the right cold storage door depends on the specific type of environment and the operational needs. Here are some key considerations:

Temperature Requirements

Choose the appropriate door material and sealing structure based on the internal temperature of the cold storage to ensure it can withstand temperature fluctuations.

Frequent Usage

For cold storage with frequent high speed roller shutter operations, consider a door with rapid open/close functionality to minimize cold air loss and enhance energy efficiency.

Durability and Low Maintenance Costs

Insulated high speed doors are designed for durability and longevity to withstand frequent use and harsh environments. Low maintenance costs are also a major advantage of choosing a cold storage door, as it reduces expenditure on equipment maintenance and replacement, further reducing the long-term costs of storage operations.